’’We have worked with FHP on a number of projects and they are consistent in their delivery of a professional and quality service. FHP also works flexibly which I think sets them apart from the competition, especially where flexibility & creativity are required for complex and challenging projects’’

"FHP has recently demonstrated its technical ability to offer an alternative cooling solution to a planning issue at the Luton Street Project - Westminster. Being able to propose innovative solutions is a differentiator that FHP is able to offer with proactivity."

"FHP deliver to our specific requirements, providing the information and detail we need. The working relationship is good. They are experienced, great to work with and responsive."

"We’ve worked very closely with FHP over the past few years, they’ve been integral in supporting tenders, development opportunities and our live projects. Their expertise in the sector has led them to being fundamental in our success over the years. They are not only extremely knowledgeable but are also always a pleasure to work with. Thanks FHP."

"We have worked with FHP on a number of residential projects, of varying scales. They have been knowledgeable and professional, with a relaxed and friendly approach. Most importantly for us, they take a flexible approach to problem solving, offering pragmatic ideas at all stages of design development."

"FHP are one of the key companies on our shortlist of MEP Consultants. They have worked successfully with us on several Galliard projects. Based on our experience to date with they are a great company to work with."

"We were initially introduced to FHP by a Trade Contractor as their specialist designer. We were so pleased with their performance we have subsequently instructed FHP on a number of schemes since and are one of our ‘go to’ designers. FHP and in particular Ryan Singh are knowledgeable and professional and always provide very prompt service. We have subsequently recommended FHP to other industry contacts and will continue to do so."

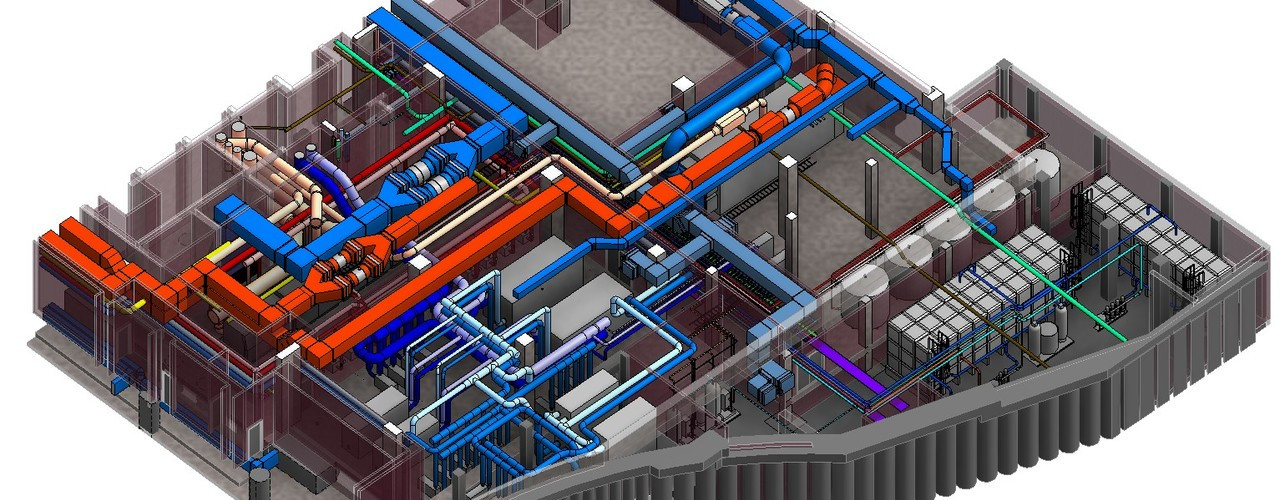

“We engaged the services of FHP on our SEGRO Park project for the design and co-ordination of the Mechanical Services installation. The design had to be undertaken in Revit within a common environment, with complicated interactions across multiple interfaces. The FHP team were extremely helpful and knowledgeable throughout the design process, offering multiple solutions to the varying issues we came across. We would recommend their services to anyone looking for a single solution to complicated engineering services design.”

"We have been working with FHP for 6 years during which they have become one of our favoured MEP Consultants. FHP consistently deliver a high standard of design and ensure design efficiency is at the forefront, providing schemes with budget in mind. FHP are easy to communicate with, offer good technical guidance and have a competent team of engineers. I’m sure we’ll work with FHP to deliver many successful future schemes and would highly recommend them."

"It was a pleasure to work with FHP on both the Bank Station Capacity Upgrade and Duke of York as part of the Victoria Station Upgrade. They bring an excellent level of professionalism and experience. FHP provided us with the “Full Package Deal” a team of cutting-edge designers, dedication and passion, going that extra mile. We look forward to working with them in the future."

_0.jpg)